Page 108 - MSAM-3-2

P. 108

Materials Science in Additive Manufacturing NiTi lattice: Performance optimization

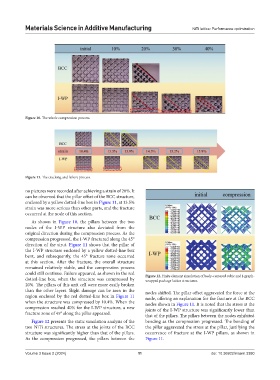

Figure 10. The whole compression process.

Figure 11. The cracking and failure process.

no pictures were recorded after achieving a strain of 20%. It

can be observed that the pillar offset of the BCC structure,

enclosed by a yellow dotted-line box in Figure 11, at 13.5%

strain was more serious than other parts, and the fracture

occurred at the node of this section.

As shown in Figure 10, the pillars between the two

nodes of the I-WP structure also deviated from the

original direction during the compression process. As the

compression progressed, the I-WP fractured along the 45°

direction of the strut. Figure 11 shows that the pillar of

the I-WP structure enclosed by a yellow dotted-line box

bent, and subsequently, the 45° fracture zone occurred

at this section. After the fracture, the overall structure

remained relatively stable, and the compression process

could still continue. Failure appeared, as shown in the red Figure 12. Finite element simulation of body-centered cubic and I-graph-

dotted-line box, when the structure was compressed by wrapped package lattice structures.

20%. The pillars of this unit cell were more easily broken

than the other layers. Slight damage can be seen in the nodes shifted. The pillar offset aggravated the force at the

region enclosed by the red dotted-line box in Figure 11 node, offering an explanation for the fracture at the BCC

when the structure was compressed by 10.4%. When the nodes shown in Figure 11. It is noted that the stress at the

compression reached 40% for the I-WP structure, a new joints of the I-WP structure was significantly lower than

fracture zone of 45° along the pillar appeared. that of the pillars. The pillars between the nodes exhibited

Figure 12 presents the static simulation analysis of the bending as the compression progressed. The bending of

two NiTi structures. The stress at the joints of the BCC the pillar aggravated the stress at the pillar, justifying the

structure was significantly higher than that of the pillars. occurrence of fracture at the I-WP pillars, as shown in

As the compression progressed, the pillars between the Figure 11.

Volume 3 Issue 2 (2024) 11 doi: 10.36922/msam.3380