Page 563 - IJB-10-2

P. 563

International Journal of Bioprinting OLS design for distal femur osseointegration

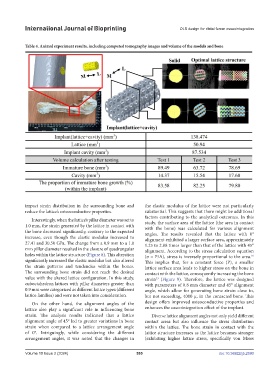

Table 4. Animal experiment results, including computed tomography images and volume of the models and bone

impact strain distribution in the surrounding bone and the elastic modulus of the lattice were not particularly

reduce the lattice’s osteoconductive properties. substantial. This suggests that there might be additional

factors contributing to the analytical outcomes. In this

Interestingly, when the lattice’s pillar diameter was set to

1.0 mm, the strain generated by the lattice in contact with study, the surface area of the lattice (the area in contact

with the bone) was calculated for various alignment

the bone decreased significantly, contrary to the expected angles. The results revealed that the lattice with 0°

increase, even though the elastic modulus increased to alignment exhibited a larger surface area, approximately

27.41 and 30.50 GPa. The change from a 0.9 mm to a 1.0 1.25 to 2.88 times larger than that of the lattice with 45°

mm pillar diameter resulted in the closure of quadrangular alignment. According to the stress calculation equation

holes within the lattice structure (Figure 8). This alteration (σ = P/A), stress is inversely proportional to the area.

16

significantly increased the elastic modulus but also altered This implies that, for a constant force (P), a smaller

the strain patterns and tendencies within the bones. lattice surface area leads to higher stress on the bone in

The surrounding bone strain did not reach the desired contact with the lattice, consequently increasing the bone

value with the altered lattice configuration. In this study, strain (Figure 9). Therefore, the lattice was designed

53

cuboctahedron lattices with pillar diameters greater than with parameters of 0.8 mm diameter and 45° alignment

0.9 mm were categorized as different lattice types (different angle, which allow for generating bone strain close to,

lattice families) and were not taken into consideration. but not exceeding, 4000 μ, in the contacted bone. This

On the other hand, the alignment angles of the design offers improved osteoconductive properties and

lattice also play a significant role in influencing bone enhances the osseointegration effect of the implant.

strain. The analysis results indicated that a lattice Diverse lattice alignment angles not only yield different

alignment angle of 45° led to greater variations in bone contact areas but also influence the stress distribution

strain when compared to a lattice arrangement angle within the lattice. The bone strain in contact with the

of 0°. Intriguingly, while considering the different lattice structure increases as the lattice becomes stronger

arrangement angles, it was noted that the changes in (exhibiting higher lattice stress, specifically von Mises

Volume 10 Issue 2 (2024) 555 doi: 10.36922/ijb.2590