Page 218 - IJB-8-1

P. 218

Nano-Hydroxyapatite Bone Scaffolds with Different Porous Structures Processed by Digital Light Processing 3D Printing

in a range from 100 to 800 µm benefited the cell migration

Z 5.40±0.05 5.43±0.03 5.41±0.04 grow inside and outside of 3D scaffolds. As for scaffolds

with larger pore sizes from 500 µm to 1500 µm, Huri

et al. and Velioglu et al. revealed that large pore size has

Size/mm Y 5.39±0.03 5.43±0.02 5.41±0.03 positive effects on cell proliferation, alkaline phosphatase

. In this work,

(ALP) activity, and calcium deposition

[39,40]

the pore sizes of P, BCC, and CPS scaffolds were within

the suggested range. Figure 4C shows the grains of HA

5.40±0.04 5.43±0.02 5.39±0.03 scaffolds after sintering at 1250°C. The clear equiaxed

grains and noticeable grain boundaries could be observed

X in SEM image, showing a good crystalline quality of the

sintered parts.

The sintered porosity of three kinds of scaffolds was

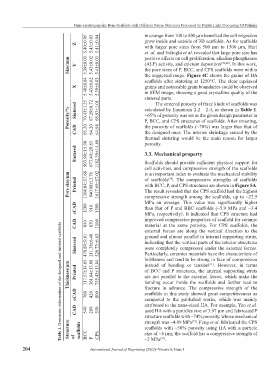

Porosity/% Sintered 70.43±1.25 67.29±0.72 68.93±1.01 calculated by Equations 2.2 – 2.4, as shown in Table 1.

~65% of porosity was set as the given design parameter in

P, BCC, and CPS structures of scaffolds. After sintering,

CAD 65.20 64.20 64.94 the porosity of scaffolds (~70%) was larger than that of

the designed ones. The interior shrinkage caused by the

thermal sintering would be the main reason for larger

porosity.

Sintered 903.90±15.90 673.40±20.63 1182.39±14.69 3.3. Mechanical property

Scaffolds should provide sufficient physical support for

cell activities, and compressive strength of the scaffolds

Pore size/µm Printed 1304.84±17.68 940.08±13.76 1617.69±17.02 is an important index to evaluate the mechanical stability

of scaffolds . The compressive strengths of scaffolds

[34]

with BCC, P, and CPS structures are shown in Figure 5A.

The result revealed that the CPS scaffold had the highest

compressive strength among the scaffolds, up to ~22.5

MPa on average. This value was significantly higher

cCAD 1280 910 1590 than that of P and BBC scaffolds (~5.9 MPa and ~3.4

MPa, respectively). It indicated that CPS structure had

improved compressive properties of scaffold for ceramic

CAD 850 630 1100 material at the same porosity. For CPS scaffolds, the

Table 1. Geometric information of the designed and sintered scaffolds

external forces are along the vertical direction to the

ground and almost parallel to internal supporting struts,

Sintered 470.89±9.61 211.38±6.48 520.73±6.63 indicating that the vertical parts of the interior structures

were completely compressed under the external forces.

Particularly, ceramics materials have the characteristic of

brittleness and tend to be strong in face of compression

Thickness/µm Printed 717.57±14.65 361.04±13.88 755.43±13.04 instead of bending or tension . However, in terms

[41]

of BCC and P structures, the internal supporting struts

are not parallel to the external forces, which make the

bending occur inside the scaffolds and further lead to

cCAD 760 420 800 fracture in advance. The compressive strength of the

scaffolds in this study showed great competitiveness as

compared to the published works, which was mainly

attributed to the nano-sized HA. For example, Yao et al.

CAD 540 280 550 used HA with a particles size of 3.97 µm and fabricated P

structure scaffolds with ~74% porosity, whose mechanical

strength was ~4.09 MPa . Feng et al. fabricated the CPS

Structure of scaffolds BCC P CPS scaffolds with ~50% porosity using HA with a particle

[15]

size of ~8 µm; the scaffold has a compressive strength of

~2 MPa .

[33]

204 International Journal of Bioprinting (2022)–Volume 8, Issue 1